Tác dụng của polymer trong xỠlý nước thải

Table of Contents

What is Polymer?

A polymer is a chemical compound made up of large molecules formed by the repetition of smaller units called monomers. Common examples of polymers in daily life include plastics and rubber. The key feature of polymers is their repeating structure, which gives them strength and flexibility.

Polymers have unique properties such as high viscosity and good absorption capacity. These characteristics make them useful in various applications. Some polymers can form gels when dissolved in water, helping control sedimentation and solid separation during wastewater treatment.

With their unique structure and flexibility, polymers are widely used in many industries. They are not only applied in wastewater treatment but also in manufacturing products like packaging and construction materials. This diversity highlights the value and potential of polymers across different fields.

Characteristics of Polymers in Wastewater Treatment

Polymers have important characteristics that enhance the efficiency of wastewater treatment. Their large molecular weight helps create strong networks, absorbing and settling pollutants more effectively, especially suspended solids.

Viscosity is another important factor; when polymers dissolve in water, they increase viscosity, creating favorable conditions for flocculation and removal of dirt particles. However, viscosity must be adjusted appropriately to avoid affecting the treatment process.

The pH of the solution also affects the effectiveness of polymers, as they perform best within a certain pH range, ensuring optimal pollutant absorption and treatment.

Working Mechanism

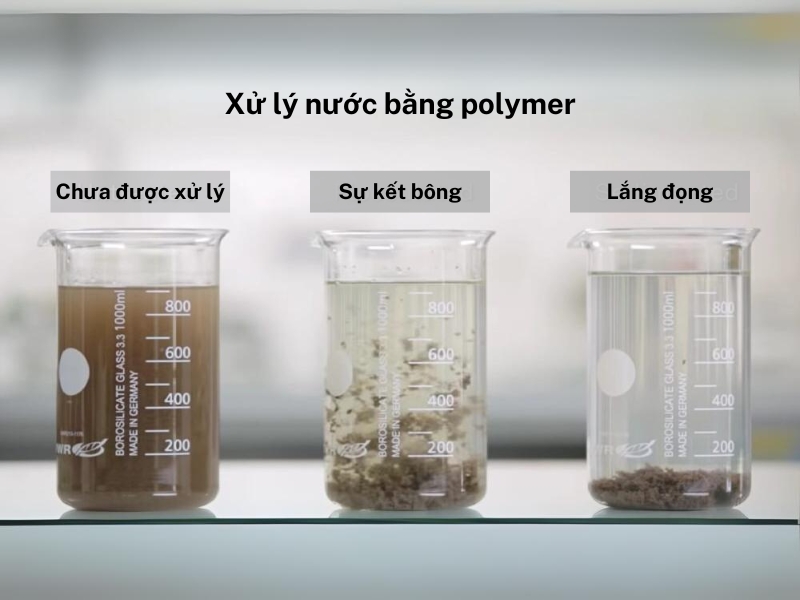

During coagulation, small colloidal particles suspended in water, which carry an electric charge that prevents them from sticking together, are neutralized by polymers. As a result, these particles begin to aggregate into small flocs.

Then, the flocculation process occurs when these small flocs continue to combine into larger flocs, which settle down and are easily removed from the water. This mechanism of polymers in wastewater treatment helps efficiently remove impurities from wastewater.

Polymers in Wastewater and Water Supply

Polymers are widely used in wastewater treatment processes to remove pollutants, from bacteria to heavy metals. At the same time, in the water supply process, polymers help improve water quality by coagulating and forming flocs, making the water clear and ensuring that the treated water is not only clean but also safe for use. Let's take a closer look at these two processes using polymers.

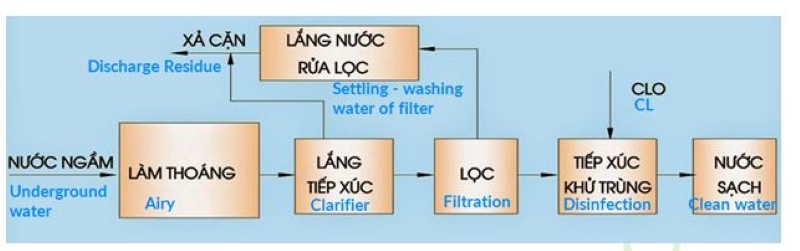

Water Supply Process

Objective: Remove impurities, bacteria, and heavy metals to provide clean water for domestic and industrial use.

Role of Polymers:

- Participate in the coagulation and flocculation stage.

- Help remove suspended impurities causing water turbidity.

How It Works:

- Polymers separate suspended impurities and assist in the settling of hydroxide flocs.

- Effectively clarify the water.

Features of Polymers:

- Non-toxic and less impact on water pH.

- Help maintain safety and stability in the treatment process.

Usage Concentration:

- Anionic polymers are typically used at concentrations between 0.1 to 1g/m² of groundwater or river water, depending on the level of pollution.

Result: Ensure that the treated water is not only clean but also safe, meeting standards for domestic and industrial use.

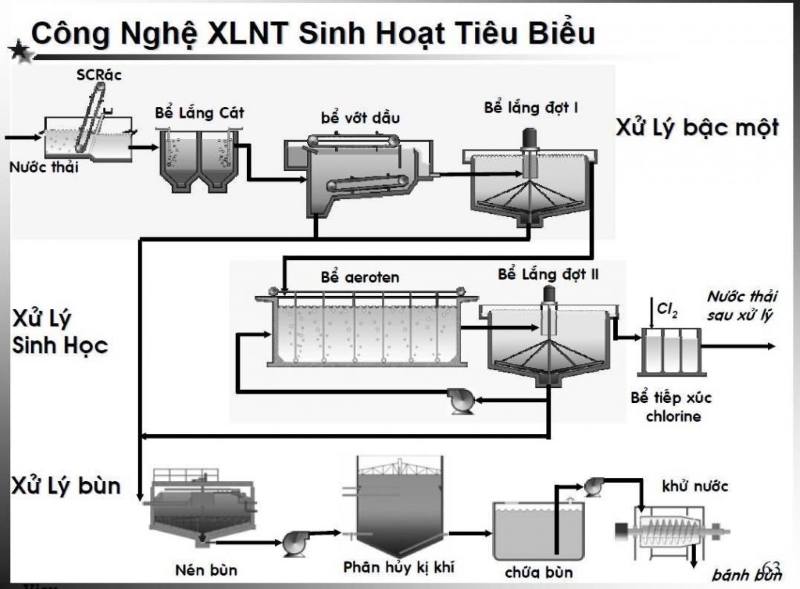

Using Polymers in Wastewater Treatment

Objective: Polymers in wastewater treatment help remove organic, inorganic pollutants, and microorganisms to protect the environment.

Role of Polymers:

- Used before the sedimentation tank to separate suspended impurities such as color, ash, and soot from exhaust gases.

Effectiveness in Different Scenarios:

- Especially effective in treating circulating water in production.

- Supports the treatment of oily and greasy wastewater when combined with flotation methods (D.A.F).

Usage Concentration:

- Anionic polymers are usually used at concentrations ranging from 1 to 50g/m² of wastewater.

- Cationic polymers can be used at 1–30g/m² of wastewater, depending on the pollution level.

Result: Optimize the wastewater treatment process, ensuring that the treated water meets discharge standards.

Classification of Polymers in Wastewater Treatment

Polymers are divided into three main groups: anionic, cationic, and amphoteric polymers, each with its own structure and application in wastewater treatment.

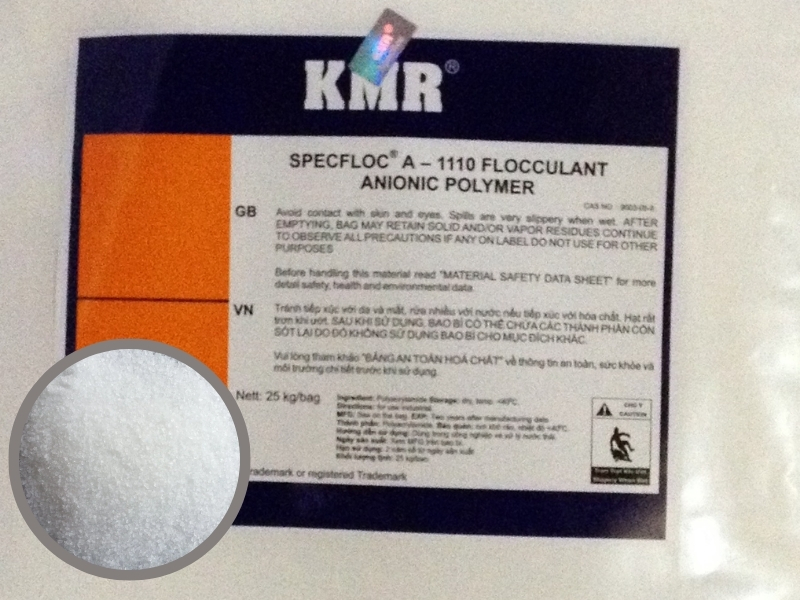

Anionic Polymers (Negatively Charged)

Anionic polymers have long molecular chains with negative charges, commonly used for coagulation and sedimentation of suspended solids in wastewater. Due to their ability to interact with positively charged particles, anionic polymers help effectively remove impurities from water.

Anionic polymers are dissolved in water to form a base solution, then pumped into the treatment system as required.

- The concentration of the base solution is usually between 0.01 – 0.2% by weight.

- The dosing system operates automatically continuously.

- The concentration used during treatment varies from 0.1 to 50 ppm.

The main applications of anionic polymers include treating industrial and domestic wastewater, where the wastewater often contains heavy metals, organic compounds, and suspended solids.

Cationic Polymers (Positively Charged)

Cationic polymers have a positive charge, allowing them to strongly interact with negatively charged colloidal particles and suspended solids in wastewater. These polymers are very effective in treating wastewater containing oil, grease, and difficult-to-degrade organic substances.

Cationic polymers are dissolved in water to form a base solution, which is then introduced into the wastewater treatment system.

- The concentration of the base solution is usually between 0.01 – 0.2% by weight.

- The dosing system always operates in automatic mode, with usage concentrations ranging from 0.1 – 20 ppm.

Cationic polymers are commonly used in industries such as chemical production, textile, paper, and domestic wastewater treatment, helping the coagulation and sedimentation process occur quickly.

>>> Learn more: Cationic Resin 220Na effectively removes water hardness

Amphoteric Polymers

- Unique Ability: Amphoteric polymers can carry both negative and positive charges on the same molecule, allowing them to adapt well to complex wastewater conditions.

- Applications: Often used in wastewater treatment processes with difficult-to-remove impurities, including industrial and domestic wastewater.

- Effectiveness: The strong adsorption and sedimentation capability of amphoteric polymers enhances treatment efficiency, especially in cases where wastewater has significant variations in pH or pollutant concentration.

Applications of Polymers

Polymers have many important applications in various fields, especially in water treatment and industry. In the field of water treatment, polymers are used to treat surface water, river water, and groundwater, helping remove dissolved impurities such as Fe²⺠and Mn²âº.

Polymers play a vital role in industrial wastewater treatment, especially in high-concentration sources containing many suspended particles and positively charged particles. They are very effective in steel mills, electroplating plants, and coal washing wastewater treatment.

Polymers are essential in wastewater treatment due to their ability to coagulate, settle, and effectively remove pollutants. Using polymers correctly helps save costs, time, and reduce environmental impact. To learn more about chemicals and water treatment equipment, contact Môi TrÆ°á»ng Song Phụng for detailed consultation.

>>> Explore our services at Song Phụng:

- UV lamp efficiency testing service

- Mobile membrane RO cleaning service for water filtration systems

Silicone Roller,Silicone Rubber Embossing Roller,Conductive Roller,Traction Transmission Roller

Jiangyin Mingda Rubber Roller Co,Ltd , https://www.mingdaroller.com