Ensuring your USB cables work properly is essential, whether you're a tech enthusiast, a DIYer, or an electronics professional. It's all about making sure your devices charge smoothly and data transfers happen seamlessly. At APPHONE, as a leading USB cable manufacturer, these tests are vital to our production process. These methods ensure that the cables we produce meet the highest quality standards. In this article, we'll go through various techniques like electrical testing, push-and-pull tests, salt spray tests, high-temperature tests, and more. These tests are performed to guarantee that our customers receive top-quality USB cables. Are you ready to make sure your USB cables are of the best quality? Let's explore how we ensure the reliability and performance of our USB cables with these testing methods; So, what is the best USB cable detection method? In this part of the article, we will share below USB cable test methods in detail. Now let’s see how you can perform these phone cable tests on your USB cables with perfection. The electrical testing method involves analyzing the electrical characteristics of a USB cable to determine its presence and functionality. It typically includes three key tests: continuity test, resistance test, and voltage level test. Here is the detail about all three electrical testing methods. At APPHONE, during USB data cable production, after the primary injection molding step, we use power detectors to test the eclectic performance of the cable. These tests are key to making sure the cables are of high quality and avoiding flow of the defective products in the next step of USB cable production. Let’s find out more about these tests. Continuity Test: If the tester shows there’s a connection for all pins, your USB cable is okay. If not, there might be a problem with the cable. Resistance Test The resistance value should be relatively low, typically within the range of a few ohms (Ω), depending on the length and thickness of the USB cable. If the resistance value is significantly higher than expected, it may indicate a problem with the cable, such as a broken connection or a faulty wire. As a general guideline, the resistance value should be consistent across all corresponding pin pairs. Significant variations in resistance between pin pairs may suggest an issue with the cable. Voltage Level Test Compare the measured voltage values with the expected voltage levels for the specific USB cable. Significant deviations may indicate issues with power delivery. Another method for phone cable testing is the push and pull force test. In this procedure, a push pull tester machine is used to apply cyclic pull forces to the cable. The machine clamp securely clamps the cable and pulls it in opposite directions to simulate the stresses and strains it may encounter during everyday use. This test is crucial for evaluating the physical robustness and durability of USB cables. By subjecting the cable to cyclic pull forces, we can assess its ability to withstand bending, pulling, and twisting forces, providing valuable insights into its overall integrity and reliability. If the cable withstands the cyclic pull forces without issues, it passes the push and pull test. The Rocking Test (Swing Tensile Test) is a crucial evaluation method for assessing the mechanical reliability and stability of USB connectors. This test is designed to mimic the typical movements that the connector may encounter during regular use. This test utilizes a swing testing machine to secure the cable and simulate the rocking motion. Here are the steps to perform this phone cable testing: By observing how the cable responds to the bending and rocking motion, it is possible to assess its ability to maintain a secure and stable connection over time, thus gauging its overall durability and reliability. If the cable bends and rocks smoothly without any signs of damage or excessive resistance, it passes the rocking test. However, if the cable feels stiff, resists bending, or shows signs of damage or breakage during test, it may indicate a problem with the cable’s construction or internal components. The unplug and plug test uses a Plug and unplug testing machine. It involves setting the insertion angle and distance of the machine and performing cyclic insertion and extraction actions on a USB cable. It is done to assess the physical connection reliability of a USB cable and its connectors. This test evaluates the cable’s ability to maintain a secure and stable connection over multiple cycles of usage, simulating real-world scenarios where devices are frequently connected and disconnected. Through this test, any signs of wear, damage, or degradation in the cable’s connectors can be identified, providing insights into its overall durability and longevity. If the cable connects and disconnects securely without any issues, it passes the unplug and plug test. If the cable feels loose or does not connect securely, it may indicate a problem with the cable’s construction or internal connections. The salt spray test is an essential evaluation method used to assess the corrosion resistance of materials, including USB cables when subjected to harsh environmental conditions. It simulates the effects of exposure to salt-laden atmospheres, such as those encountered in marine or outdoor settings, where corrosion can occur rapidly. During the salt spray testing, USB cables are placed in a sealed chamber or cabinet, where they are exposed to a fine mist of saltwater solution. This mist creates a corrosive environment that accelerates the natural corrosion process, allowing testers to assess how well the cable’s materials and coatings withstand such conditions. Throughout the test, technicians periodically inspect the USB cables for signs of corrosion, such as rust, discoloration, or degradation of materials. These observations are recorded and analyzed to determine the cable’s corrosion resistance and suitability for its intended application. Equipment Needed: Salt spray chamber, USB cables, Salt solution (mixture of sodium chloride (NaCl) and distilled water). USB cables that show minimal or no signs of corrosion after the salt spray test are considered to have good corrosion resistance. USB cables that exhibit significant corrosion or damage may not be suitable for harsh environments and may require additional protective measures or alternative materials. The temperature test and high-temperature test are essential methods for evaluating the performance and reliability of USB cables under varying temperature conditions in a thermostatic chamber. These tests assess the cable’s ability to function properly within specified temperature ranges and its resistance to extreme heat. Here’s an overview of both tests: The temperature test involves exposing the USB cable to a range of temperatures, typically from -40°C to 85°C, to simulate different environmental conditions. The cable’s performance is monitored throughout the test, including its electrical characteristics, data transmission capabilities, and physical integrity. Equipment Needed: Steps to Perform this Test: USB cables that pass the constant temperature test and high-temperature test without any significant performance degradation or physical damage are considered to meet the specified temperature requirements. Cables that exhibit performance issues or damage during the tests may require design modifications or alternative materials to improve their temperature resistance. USB cables are essential for connecting devices and transferring data, but they can become damaged or malfunction over time. Detecting issues with USB cables early is crucial to prevent data loss, and hardware damage, and ensure reliable performance. Here are some key reasons why USB cable detection is important: Jiangsu Jiali New Material Technology Co., Ltd. , https://www.jlmaterial.com

What Are the USB Cable Detection Methods?

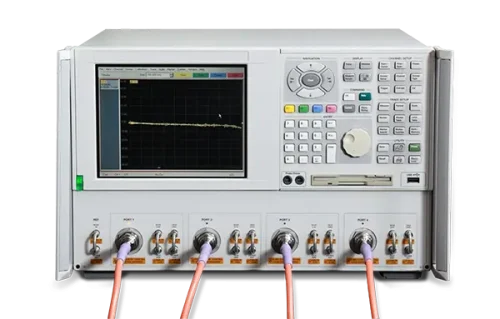

Electrical Testing Methods

The continuity test is best to perform when validating the connection of wires within the USB cable and for proper data line testing. It will ensure uninterrupted data transmission. It entails the passage of a low electrical current through the wires while gauging the resistance. A consistent and low resistance reading signifies that the wires are effectively connected, affirming seamless data flow. Here’s how to perform a continuity test on a USB cable with a power detector:

Equipment Needed: Power Detector;

Steps to Perform this Test:

The resistance test is performed to measure the resistance of wires within the USB cable to pinpoint any instances of breaks or damage. By measuring resistance at various points along the cable, deviations in resistance levels can indicate potential issues such as fractured wires or damage compromising conductivity. Here’s how to perform a resistance test on a USB cable:

Equipment Needed: Power Detector

Steps to Perform this Test:

The voltage level test scrutinizes the voltage levels across the power lines of the USB cable to ascertain its ability to deliver requisite power to connected devices. This test entails measuring the voltage at different points along the cable. Significant deviations from expected levels may indicate deficiencies in the cable’s power delivery capabilities.

Equipment Needed: Power Detector;

Steps to Perform this Test:

The electrical testing methods we just discussed could also be done with a multimeter if you are testing a USB cable individually. However, large-scale production demands dedicated electrical testing equipment. At APPHONE, we utilize power detectors to ensure each USB cable meets our stringent quality standards, guaranteeing a reliable product for our customers.

Advantages and Disadvantages of Electrical Testing Methods

Advantages

Disadvantages

Highly accurate and reliable in detecting cable functionality;

Provides detailed information about the electrical characteristics of the cable;

Useful for diagnosing specific problems with the cable;Requires specialized equipment and technical expertise;

Can be time-consuming, especially when testing multiple cables;

Push and Pull Test

Steps to Perform this Test:

Advantages and Disadvantages of Push and Pull Test

Advantages

Disadvantages

Automated testing process eliminates subjective assessment.

Provides consistent and repeatable results.

Useful for identifying potential weaknesses in cable construction.Requires specialized equipment.

May not detect internal damage.

Limited to physical aspects of cable durability.

Rocking Test (Swing Tensile Test)

Advantages and Disadvantages of Rocking Test (Swing Test)

Advantages

Disadvantages

Provides a consistent and repeatable test method.

More accurate and reliable than manual testing.

Can perform a large number of tests quickly.

Results are less subjective than manual testing.Requires specialized equipment.

Limited diagnostic capabilities.

Not suitable for detecting internal damage.

Unplug and Plug Test

Steps to Perform this Test:

Advantages and Disadvantages of Unplug and Plug Test

Advantages

Disadvantages

Provides consistent and repeatable test results;

Minimizes the risk of damaging the cable or connectors;

Can perform a large number of cycles quickly;

Can detect intermittent faults;

Requires minimal human intervention;Requires specialized equipment;

May not identify all types of connection issues;

Limited diagnostic capability;

Salt Spray Test

The test duration can vary depending on the specific standards or requirements set by regulatory bodies or industry standards. Typically, USB cables are subjected to the salt spray for a predetermined period, ranging from several hours to days or even weeks.

Steps to Perform this Test:

Remember, salt spray testing provides valuable insights into the corrosion resistance of USB cables, but it is important to consider other environmental factors and real-world conditions when assessing the overall durability and reliability of the cables.

Advantages and Disadvantages of Unplug and Plug Test

Advantages

Disadvantages

Provides accelerated assessment of corrosion resistance;

Allows for early detection of potential corrosion issues;

Helps in evaluating the effectiveness of protective coatings;

Widely recognized and standardized test method;

Can be used to compare the corrosion resistance of different materials;Requires specialized equipment and facilities;

Test results may vary depending on test parameters;

Test duration can be lengthy, impacting time and cost;

Results interpretation may require expertise;

Temperature Test and High-Temperature Test

The high-temperature testing focuses specifically on the cable’s ability to withstand extreme heat. It involves exposing the cable to elevated temperatures, often exceeding 85°C, for a specified duration. This test evaluates the cable’s resistance to melting, insulation degradation, and other heat-related failures.

Please keep in mind that APPHONE’s test conditions (such as temperature range, duration, and evaluation criteria) can be customized according to the intended use of the customer’s USB cable.

Advantages and Disadvantages of Temperature Test

Advantages

Disadvantages

Simple and easy to perform;

Provides basic insights into cable performance at different temperatures;

Helps in evaluating the effectiveness of protective coatings;

Helps identify potential issues with cable materials and insulation;Does not provide detailed information on cable behavior under load;

Results may vary depending on test setup and conditions;

Limited applicability for assessing high-temperature performance;What is the Importance of USB Cable Detection?

Damaged or faulty USB cables can lead to intermittent connections or complete failure, resulting in data loss during transfers. Early detection of cable issues allows you to take prompt action, such as replacing the cable or transferring data using an alternative method, to minimize the risk of data loss.

Defective USB cables can cause power surges or fluctuations, potentially damaging connected devices. By detecting cable problems early, you can prevent damage to sensitive electronic components, such as smartphones, laptops, external hard drives, and other peripherals.

Faulty USB cables can cause slow data transfer speeds, connection errors, and device malfunctions. Detecting and resolving cable issues ensures optimal performance and a seamless user experience.

Intermittent connections and data transfer